Home Labels and Tags

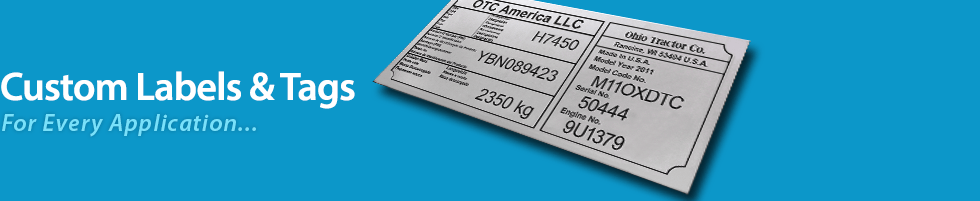

Custom Labels and Equipment ID Tags

Lasting the Life of Your Assets With No Need for Re-Labeling

MPC’s labels, tags and heavy-duty, industrial stickers are built to last – giving you the assurance that your assets will be easily identified for the life of the part. Choose from durable metal labels and plastic labels pre-printed with constant or variable data, human readable content or bar codes. Need real-time production of tags or stickers? Select our metal blanks to mark yourself using your own laser marking, engraving, stamping or other processes.

Our metal and plastic labels and blanks are ideal for equipment tags used in offices, locker rooms, machine shops, warehouses, heavy-duty industrial applications and even harsh exterior environments. They meet many Department of Defense and aerospace specifications, as well as other industry standards.

Our advanced printing and fabrication capabilities will produce a label or tag that’s best for your application, including a selection of graphics, die cutting, adhesives and mechanical attachments.

Contact us today for help with your application.

Custom Labels, Tags and Stickers for Any Application

Durable metal and plastic label options to meet the requirements of any application. We offer exclusive options for especially demanding environments that feature durablility unmatched by any other label materials.

- A wide array of adhesives and mechanical attachment options available to ensure your labels stay attached for the life of your asset.

- High resolution black and white or full color options.

- Metalphoto options built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Barcode and QR code options for asset tracking are available.

Durable metal and plastic label options to track and identify assets and parts across any application. Extremely durable options for harsh outdoor environments and polyester stickers for less volatile, indoor environments.

- A wide array of adhesives and mechanical attachment options available to ensure your labels stay attached for the life of your asset.

- High resolution black and white or full color options.

- Metalphoto options built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Feature barcodes and QR codes for tracking and linking to information.

Our identification products feature durability superior to all other options, including stainless steel in many environments, because it is created using our proprietary Metalphoto® substrate.

- Customized to the size, shape, thickness and information you need.

- High-performance adhesive and/or holes for mechanical attachment.

- Metalphoto options built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Feature barcodes and QR codes for tracking and linking to information.

Custom metal decals can be customized to contain any information your application requires, including anything from bold text to logos, variable barcoded data, and detailed schematics.

- Customized to the size, shape, thickness and information you need.

- High-performance adhesive and/or holes for mechanical attachment.

- Metalphoto options built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Feature barcodes and QR codes for tracking and linking to information.

Metal and plastic asset labels with options to resist tampering, removal or counterfeiting of label or the asset to which the label is affixed.

- Metal options with a watermark or security print options, similar to those found in pidentification cards and currency.

- Tamper evident labels that leave permenant evidence on the asset if removed.

- Destructible labels that fracture and break apart if detached from an asset.

- Two-part labels with a second tab containing the tag information that easily attaches to your records.

MPC’s custom metal number tags are manufactured to contain whatever information your tag requires – from bold text to detailed schematics to variable barcoded data.

- Customized to the size, shape, thickness and information you need.

- High-performance adhesive and/or holes for mechanical attachment.

- Metalphoto options built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Available with constant or variable data.

Stamped metal tags from MPC can be manufactured to your specifications with any information required, such as bold text, logos, detailed schematics, compliance information, serial numbers, and variable barcoded data.

- Customized to the size, shape, thickness and information you need.

- High-performance adhesive and/or holes for mechanical attachment.

- Metalphoto options built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Available with constant or variable data.

Durable metal rating plate labels identify a piece of equipment’s manufacturer, serial/model number, date of manufacture, load rating, electrical specifications, operating/maintenance instructions and other required data.

- Skillfully fabricated in our machine and print shops to your design specifications.

- Feature barcodes or QR codes for asset tracking or to link to critical asset information.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- High-performance adhesive and/or holes for mechanical attachment.

Also known as data plates, rating plates or nameplates; compliance tags identify required information about a piece of equipment.

- Feature barcodes or QR codes for asset tracking or to link to critical asset information.

- Created using Metalphoto, an aluminum substrate used in defense and aerospace applications due to its durability.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- High-performance adhesive and/or holes for mechanical attachment.

Pre-printed metal or plastic labels, or label blanks for onsite marking that contain variable information about your assets.

- Durable metal or plastic options.

- Feature barcodes or QR codes for asset tracking or to link to critical asset information.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Available pre-printed or as blanks for onsite marking.

MPC’s Vin Tags offer unmatched durability and graphic flexibility to some of the world leaders in transportation.

- Specified for many military standards and aerospace applications.

- High-performance adhesives and/or holes for mechanical attachment.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Proclaimed as the most durable aluminum substrate by the National Association of Graphic and Product Identification Manufacturers (GPI).

Durable metal labels that identify operating, maintenance, warning, or other instructions and procedures for your equipment.

- Customizable size, shape, thickness and information.

- Feature barcodes or QR codes for asset tracking or to link to critical asset information.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- High-performance adhesive and/or holes for mechanical attachment.

Durable metal or plastic labels that provide essential information about an electrical panel necessary for operation, maintenance, and repairs.

- Images sealed beneath a sapphire-hard layer of photosensitive anodized aluminum face stock.

- Professionally fabricated in our machine and print shops to your design specifications.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- High-performance adhesives and/or holes for mechanical attachment.

Durable metal or plastic labels that provide essential information about an electrical panel necessary for operation, maintenance, and repairs.

- Skillfully fabricated in our machine and print shops to your design specifications.

- High-performance adhesives and/or holes for mechanical attachment.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years.

- Specified for many military standards and aerospace applications.

MPC’s brass tags are a popular choice for both industrial and decorative applications due to their durability and striking appearance.

- Durability to withstand indoor and outdoor conditions.

- Skillfully fabricated in our machine and print shops to your design specifications.

- Excellent resistance to saltwater, corrosion, tarnish, chemicals, solvents and extreme temperatures.

- Attachment options include high-performance adhesives and/or holes for mechanical attachment.

Electrical wire labels are crucial for safety and compliance, providing essential information for identifying and repairing electrical control panels other electrical components.

- Withstands years of exposure to extreme heat, humidity, UV, salt spray, abrasion, industrial solvents, chemicals and more.

- Proclaimed as the most durable aluminum substrate by the National Association of Graphic and Product Identification Manufacturers (GPI).

- Skillfully fabricated to your design specifications in our machine and print shops.

- Attachment with high-performance adhesives and/or holes for mechanical attachment.

A robust, malleable metal with excellent resistance to saltwater, corrosion, chemicals and solvents, tarnish, and extreme temperatures, brass valve tags are suitable for both indoor and outdoor applications.

- Suitable for both indoor and outdoor applications.

- Skillfully fabricated in our machine and print shops to your design specifications.

- Excellent resistance to saltwater, corrosion, tarnish, chemicals, solvents and extreme temperatures.

- Attachment options include high-performance adhesives and/or holes for mechanical attachment.

Durable metal blank labels that can be marked onsite using engraving, stamping, embossing or laser marking processes.

- Available in a variety of sizes, thicknesses, materials and finishes.

- Marked onsite at your facility.

- Options with durability that can withstand extended outdoor use available.

- High-performance permanent adhesive and/or holes for mechanical attachment.

Benefits of Equipment Labels

Equipment labels and tags are common in most industries today because they make it easy to track and manage valuable company assets. With several high-quality label materials available, companies can select the ideal style of equipment ID label most suitable for each application. Some examples of the types of assets that are frequently labeled include:

- Computers and IT equipment

- Fleets, such as trucks and commercial passenger vehicles

- Military and aerospace equipment

- Industrial equipment

- HVAC equipment

- Utility assets, such as utility poles and meters

- Medical devices, such as defibrillators

Equipment labels are used for a variety of purposes beyond asset identification, as well, such as warning or caution labels, inspection and compliance tags, instructional labels, rating plate labels, and more. Custom labels and tags offer many benefits, including:

- Effective Tracking. One of the most important reasons for using equipment labels is the ability to locate moveable assets when they’re needed. This is especially true for large facilities or multi-site operations when assets are transferred between locations. Labeling each piece of equipment with an equipment ID label with a barcode allows you to maintain a central database of your moveable assets in an enterprise asset management (EAM) system. When equipment tags are equipped with barcode labels, assets can be easily scanned to document its current location as well as important usage data. Maintaining a central asset database with real-time data means assets are less likely to be lost, saving your business money on costly equipment replacements.

- Modernized Systems. Equipment tags enable efficient inventory and asset management by allowing you to connect each asset to a digital system. Labels that include barcodes can be easily used with today’s software platforms and barcode readers to give companies better visibility into their assets. These modern facilities management solutions are affordable, save time for your staff, and create a reliable tracking history. Using equipment ID labels not only helps with regulatory compliance and audits but can also prevent theft and unauthorized transfer by clearly identifying ownership.

- Easily Communicate Essential Information for Safety & Compliance. Custom labels and tags can be used to convey critical safety information, such as warning labels or safe operating instructions. Proper labeling improves workplace safety and helps to ensure compliance with relevant safety regulations, such as FMCSA regulations for truck and trailer data plates and GHS requirements for hazard communication labels.

- Improved Maintenance Management. Equipment labels allow for more efficient maintenance management. They can be used in conjunction with preventive maintenance software to track all maintenance activities for each asset, and many software solutions offer alerts to notify your maintenance management staff when an asset is due for routine maintenance. Maintenance workers can easily scan an asset’s barcode to accurately document maintenance and repairs performed. Staying on top of preventive maintenance helps to keep your valuable equipment in optimal working order, reducing unexpected breakdowns and workflow interruptions.

- Customization. One of the best reasons for selecting equipment labels is the ability to customize them in any way you like. Selecting colors, designs, and fonts can help you create equipment ID labels that match your existing corporate branding. Label substrate, finish, and adhesive options give you the confidence to select materials that are well-suited for the operating environment and any potential environmental conditions. You can also select barcode symbologies that are compatible with your scanning equipment and software.

Common Use Cases for Equipment Tags

- Aerospace and Defense Compliance Tags. The aerospace and defense industries are regulated by a number of standards that define how assets must be tracked. These can apply to important choices including the type of technology that is used and the materials of construction for an equipment label. In order to ensure compliance, many companies turn to high durability options such as Metalphoto® equipment tags.

- Commercial HVAC Nameplates. The HVAC units that are used in commercial facilities take a tremendous burden and must often operate under extreme weather conditions and for extended periods of time. Customized equipment labels that are used for HVAC drives and generators must be able to withstand these harsh environments without degradation. Many vendors use custom equipment tags that can be fabricated with durable substrates that are well-suited for these conditions.

- Industrial & Manufacturing Instructional Labels. Instructional labels are used for equipment with specific maintenance requirements or operating instructions to clearly convey essential information to ensure the safe and efficient operation of equipment and required maintenance steps to keep assets in optimal working condition.

- Rating Plates for Trucks, Trailers & Equipment. The transportation industry is subject to regulations under FMCSA and NHTSA, which require that vehicles are marked with information such as the vehicle make and model, VIN number, gross vehicle weight rating (GVWR), brake system, and more. Equipment used in other industries is subject to various regulations, as well, requiring equipment to have permanent rating plate labels, data plates, or compliance tags containing the equipment’s manufacturer, model number or serial number, load rating, and electrical specifications, as well as any essential operating or maintenance information.

No minimum quantity. Get a quote for any size job.

No minimum quantity. Get a quote for any size job.

Labels & Tags