Home Stamped Metal Tags

Stamped Metal Tags

Designed to Last the Life of Your Product

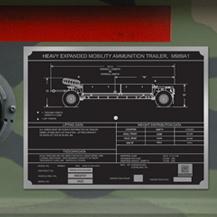

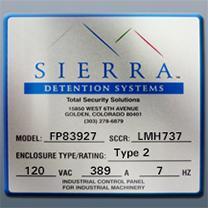

Stamped metal tags from MPC can be manufactured to your specifications with any information required, such as bold text, logos, detailed schematics, compliance information, serial numbers, and variable barcoded data.

When constructed of Metalphoto® photosensitive anodized aluminum, stamped metal tags offer exceptional durability, making them suitable for use in applications requiring permanent product or process information. Metalphoto stamped metal tags have the image sealed inside the anodized aluminum, which provides added durability, ensuring readability for years in harsh environments. In fact, Metalphoto stamped metal tags offer excellent resistance to corrosion, sunlight degradation, abrasion, extreme temperatures and chemical exposure and have an expected exterior life of 20+ years.

Stamped metal tags are available in matte, satin, and gloss finishes and various thicknesses. Attachment methods include holes for mechanical attachment or a high-performance pressure-sensitive 3M adhesive that permanently bonds to plastic, wood, metal, and other surface materials. MPC’s experienced engineers will work closely with you to select the most appropriate materials, finish, and other design options to meet your application’s requirements.

Why Choose MPC’s Stamped Metal Tags?

- Customized to the size, shape, thickness and information you need.

- Provides superior resistance to chemicals, abrasion, solvents, extreme temperatures and UV.

- Expected exterior life of 20+ years. Color options are less resistant to UV.

- Silver-colored face stock is high-contrast and easy to read.

- High-performance adhesive and/or holes for mechanical attachment.

- Available with constant or variable data.

Product Specification

| Material: | Photosensitive anodized aluminum face stock (optional thicknesses .003”, .005”, .008”, .012”, .020”, .032”, .063”, .090”, .125”). |

| Finishes: | Matte – Non-reflective w/flat finish; Satin – Lustrous semi-reflective material; #4 – Brushed to resemble a stainless steel finish; Gloss – Highly reflective, mirror-like. Note: Finish options may vary by material thickness. |

| Attachment: | Permanent pressure-sensitive adhesive and/or holes for mechanical attachment. |

| Copy/Graphics: | Many fonts and design elements are available, as well as your company logo. |

| Colors: | Black graphics on silver background or silver graphics on black background; color options available. Note: Colors other than black possess limited UV resistance. |

| Standard Sizes: | Standard and custom sizes. |

| Shipment: | 15 working days from receipt of order and approval of artwork. Expedited shipment is available for an additional charge. Foil thicknesses require 15-20 working days. |

Benefits of Stamped Metal Tags

MPC’s stamped metal tags are suitable for both indoor and outdoor environments and can be used in harsh conditions thanks to their excellent durability. Here are just a few of the benefits of MPC’s stamped metal tags.

- Long lifespan. Offering excellent resistance to a variety of environmental and operating conditions, including UV, extreme temperatures, corrosion, abrasion, and chemicals and solvents, Metalphoto® stamped metal tags have an expected exterior lifespan of more than 20 years.

- Customizable. MPC’s stamped metal tags are manufactured to your application and design specifications. From varying thicknesses to matte, satin, or gloss finishes, and many fonts and other design options, stamped metal tags can be customized to suit your application’s requirements. Our engineers will work with you to select the best materials and other design options to meet your requirements while offering both the aesthetics and durability your application requires.

- Multiple attachment options. Choose from a high-performance, pressure-sensitive adhesive to bond stamped metal tags to metal, wood, plastic, or any surface material permanently. For applications in which permanent tags aren’t suitable, stamped metal tags can also be manufactured with holes for mechanical attachment.

Common Use Cases for Stamped Metal Tags

Thanks to their excellent durability in indoor and outdoor environments, MPC’s stamped metal tags can be used for a wide range of applications.

- Pipe, wire and cable, valves, and other components. The versatility of stamped metal tags, including various size options and attachment methods, makes them suitable for applications in which adhesive attachment isn’t practical. When manufactured with holes for mechanical attachment, stamped metal tags are ideal for use as valve tags, cable and wire markers, pipe labels, and similar applications.

- Property identification. Stamped metal tags printed with your company name, logo, and the item’s unique identification or serial number is useful for establishing property ownership and deterring theft and unauthorized transfer.

- Inspection and compliance marking. For assets that must meet specific regulatory criteria for certification, stamped metal tags can be used to mark certified assets or confirm that an inspection has been performed and the asset deemed to meet standards on a specific date.

No minimum quantity. Get a quote for any size job.

Get a quote for any size job – we have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

No minimum quantity. Get a quote for any size job.

Labels & Tags