Home Metalphoto Overview

Material: Metalphoto Anodized Aluminum

Unmatched Durability and Graphic Capabilities

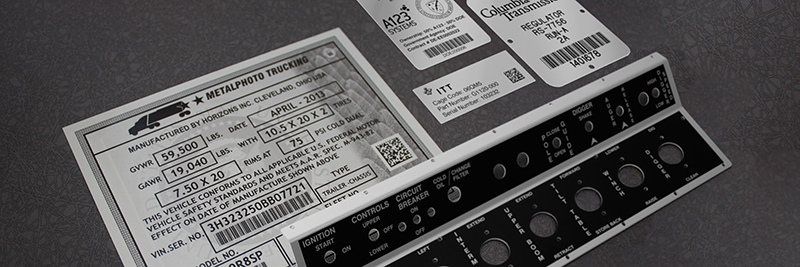

The National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual identifies Metalphoto photosensitive anodized aluminum as the most durable printed aluminum substrate available, citing its applicability for extreme environmental conditions and outdoor exposure. It is an ideal choice for those designing nameplates, front panels and tags that need to last. Metalphoto performs and remains legible for decades in the harshest environments and most challenging applications. The material is durable and the graphics are high contrast with excellent resolution.

About Metalphoto

Performance History (Video 1)

Durability (Video 2)

Image Resolution (Video 3)

Variable Information (Video 4)

Material Characteristics

Imaging: | The images/graphics for your nameplate or panel are photographically imaged into the anodic layer of the aluminum giving you an image in black or gray-scale. Additionally, color can be screen printed into the anodic layer. |

Thicknesses: | .003″, .005″, .008″, .012″, .020″, .032″, .063″, .090″ and .125″ |

Finishes: |

|

Metalphoto Performance Characteristics

| Test Results | |

| Characteristics | Result |

| Abrasion Resistance | No pronounced image loss, degradation, or reduced readability after 7000 cycles of an abrading wheel. |

| Acid Corrosion | No deterioration or image degradation after 24 hours in 3% nitric acid. |

| Heat Resistance | No legibility loss or degradation when subjected to 650°F. No deleterious effect after a 720-hour salt spray (fog) test. 2,6 |

| Salt Spray Corrosion | “Very good” corrosion resistance after 113 days seawater exposure. |

| Accelerated Light and Weather Resistance | No pronounced deterioration of legibility after 400-hour carbon arc weatherometer exposure. |

| Accelerated Oxygen Aging | No discoloration or fading after 96hour/300 psi/70°C oxygen bomb aging. |

| Stain Resistance | No black fading when plates are exposed to tincture of iodine. |

| Cleaning Resistance | No deleterious effects when tested with alkaline cleaners (MIL-C-87937 or equivalent) for aircraft surfaces. |

| Low Temperature Resistance | No deleterious effect or image fade after 1 hour at -50°F. No impairment of legibility upon exposure at -67°F. |

| Organic Solvent Resistance | No softening, staining, or noticeable fade after 24-hour exposure to: JP-4 fuel, Gasoline, Mineral spirits, Methyl ethyl ketone, Turpentine, Turbine & jet fuel, Kerosene, Xylol, Acetone, Toluol, Heptane, Trichlorethylene, MIL- H-5606 hydraulic fluid, and MIL-L-7808 jet engine oil |

| Fungus Resistance | Visual reading of “0” per ASTM-G21. |

| Thermal Shock | No deterioration after 3 cycles between -65°C and 125°C. |

| Moisture Resistance | No deterioration after 10 humidity cycles per MIL-STD-202, method 106. |

| The above tests were conducted in strict laboratory conditions. In order to achieve maximum satisfaction we highly recommend that any customer considering use of this product test the labels in the environment in which they will be used. Metalphoto of Cincinnati does not warrant performance of its materials in any environment. | |

The National Association of Graphic and Product Identification Manufacturers (GPI) Industry Standards and Practices Manual identifies Metalphoto photosensitive anodized aluminum as the most durable printed aluminum substrate available, citing its applicability for extreme environmental conditions and outdoor exposure. It is an ideal choice for those designing nameplates, front panels and tags that need to last. Metalphoto performs and remains legible for decades in the harshest environments and most challenging applications. The material is durable and the graphics are high contrast with excellent resolution.

View the Complete Results of Metalphoto’s Durability Testing

Anodized Colors

Gold (MP 100) | Yellow (MP 60) | Black (MP 80) | Orange (MP 70) | Brown (MP 75) |

Green (MP 27) | Dark Green (MP 25) | Dark Blue (MP 40) | Blue (MP 41) | Light Blue (MP 42) |

Violet (MP 45) | Magenta (MP 50) | Red (MP 51) | Burgundy (MP 53) |

Metalphoto of Cincinnati is a Certified Metalphoto Converter.

What are the Benefits of Metalphoto®?

Metalphoto® continues to be a leading material choice for some of the most demanding applications. Known for its durability and high-performance characteristics, Metalphoto has several advantages over other substrates. These are two of the most important factors that many customers consider when selecting Metalphoto for their applications.

- High-Resolution Graphics. When graphics are printed on a Metalphoto substrate, they are sealed beneath an anodic layer of aluminum. This process helps preserve and protect the high-resolution, high-contrast graphics and reduces the risk of any damage to the surface that could hinder readability. It also helps eliminate the effects of exposure to outdoor environments and other harsh conditions, making Metalphoto anodized aluminum is an excellent choice for high-quality labels, panels, and tags. Metalphoto’s excellent durability is often one of the primary reasons it’s a substrate of choice for asset management and item identification.

- Excellent Durability. Metalphoto can withstand some of the most challenging conditions in industries with assets that are exposed to harsh environmental conditions. Metalphoto labels and tags can last for up to 20 years in outdoor environments and survive persistent exposure to weather and UV rays. The Metalphoto surface is also strong enough to withstand abrasion with no pronounced image loss, degradation, or reduced readability, and it has good resistance to moisture, corrosion due to salt spray, alkaline cleaners, and other chemicals and solvents. Standard Metaphoto surfaces are resistant to temperatures up to 500°F.

Common Use Cases for Metalphoto® Nameplates, Panels, and Tags

Due to its strength and durability, Metalphoto is often selected for the most difficult and challenging applications. Metalphoto is frequently used to fabricate panels and equipment labels used in aircraft, heavy machinery, and ocean vessels. You will also find Metalphoto labels used to tag high-value assets that require added security and reliability. The military and defense industry, for instance, is governed by a number of specifications that require particular quality standards for the Unique Identifier (UID) barcode labels used for tracking purposes. Metalphoto has been a material of choice for industrial and military engineers for more than 50 years for applications in which permanent item identification is critical.

- Control Panels for Offshore Cranes. Equipment used in marine applications are exposed to salt spray, wind, water, and significant wear and tear from the harsh marine environment. Metalphoto is one of the few materials that can be used to fabricate control panels and other components for ships and marine cranes. Metalphoto control panels can be designed with custom graphics and installed integrated seamlessly with an existing setup.

- Fleet Tracking. The typical transportation fleet includes many constantly moving vehicles that must be managed with a high level of precision. Metalphoto VIN tags, nameplates, and safety data plates provide important information to drivers, inspectors, and other personnel, and they’re also required for regulatory compliance. Metalphoto is the material of choice to ensure tags, nameplates, and safety data plates remain readable for decades in the harsh environmental conditions transportation equipment endures.

- Medical Device Identification. Metalphoto is also used frequently for industrial and medical applications in which equipment and other assets are exposed to high heat. One example of this is the sterilization of medical components and samples. The labels used in these situations must withstand repeated exposure to heat while remaining legible. Metalphoto not only provides the durability required for these applications, but it’s also adequate for maintaining a sterile surface which is required for regulatory standards.

No minimum quantity. Get a quote for any size job.

MPC