Local conditions determine the best use cases for different label materials. Many enterprises have facilities with harsh operating environments and need a sturdy material that can withstand exposure to outdoor elements, chemicals and solvents, abrasion, and other potential conditions that could render an equipment nameplate unreadable. Metal is the best selection in such scenarios. So, what should a company consider when picking metal labels?

The world can be a demanding place. Whenever assets are located or transported outdoors, they are exposed to items, like rain, snow, extreme temperatures, and ultraviolet light. In select instances, corrosive chemicals are present. The chances for abrasion rise where sand, dirt, and sometimes water are common. In many manufacturing and shipping settings, dents and abrasions arise from various collisions.

So, enterprises need a tough material to mark their facilities and equipment, and metal emerges as the best option. In fact, some industries, such as aerospace and defense, mandate that companies use it to mark their assets.

Metal Label Use Cases

Metal markers are packaged in many ways and serve different purposes. Here are a few common type of metal labels to consider for your applications.

Metal Labels & Tags

Metal tags and labels, which support indoor and outdoor applications, offer companies exceptional durability. They are also flexible and can be fabricated using a large selection of graphic, die-cutting, adhesive and mechanical attachment options to meet unique application demands.

Re-writeable Metal Labels

Assets, in many cases, last years and even decades. Consequently, their naming conventions may morph through the years. Rather than throw out the existing markers and buy new ones, re-writeable tags and labels enable corporations to wipe their markings clean with isopropyl alcohol and then reuse the tag.

Blank Metal Tags & Labels

Blank labels are easy to mark and remain readable for the life of the part because they offer tough performance through sustained outdoor exposure, extreme temperatures, chemical exposure, and cleaning processes. They come in a variety of colors and finishes. They have different attachment options. Clients choose either standard or custom shapes and sizes.

Foil Metalphoto® Labels & Tags

Foil Metalphoto® labels are made of flexible aluminum and resist chemicals, abrasion, solvents, extreme temperatures, and UV rays. They work well on curved or uneven surfaces. As a security measure, they will break apart if removed from their mating surface.

Rigid Metalphoto® Labels & Tags

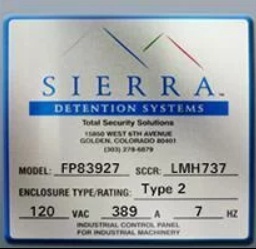

Rigid Metalphoto® tags are well suited to the outdoors: their life expectancy is more than 20 years. Use cases include asset tracking and product identification labels, property ID tags, instructional labels, safety/warning/caution labels, schematic diagrams, and machine data labels.

Custom Metal Product Labels

Custom metal label solutions offer a range of capabilities: bold text, detailed schematics, and variable barcoded data. They can be paired with high-performance pressure-sensitive adhesives that attach securely to metal, plastic, wood, and other surfaces.

A Few Buying Considerations

Use cases aren’t the only consideration when buying metal equipment nameplates. Organizations need to evaluate how well the materials fit their environment, what they will be connected to, their durability, and adherence to industry standards.

Compatibility

Always compare the demands of the work environment with the specifications of each label material. Most metals are durable, and some provide unique protection against extreme temperatures, moisture, and other contaminants.

Attachment Method

Most metal equipment ID tags are rigid and must be attached to a flat surface using an adhesive, bolts, or another mechanical method. Some labels, such as foil equipment tags, are more flexible and can often be placed on textured or curved surfaces. Before making a purchase, consider the points of attachment for any equipment that will be tagged. This step ensures that the metal equipment tags can be attached securely to your equipment.

Durability

Metal equipment nameplates can be made of several metals, including Metalphoto® anodized aluminum, anodized aluminum, aluminum, stainless steel, and brass. Some metals offer better durability in certain applications. Metalphoto® metal equipment labels have a lifespan of up to 20 years, even when used in challenging outdoor conditions or in marine applications. These plates can withstand exposure to saltwater, heat, sunlight, and sources of abrasion without significant degradation to the metal surface.

Cost Efficiency

The long shelf life of metal equipment nameplates means fewer replacements and a more reliable plate structure versus many other materials. The nameplates are also easy to install and can be attached permanently to a suitable surface. They support a number of use cases, including marine environments, where labels often quickly decay due to salt and water exposure.

Design Flexibility

A metal equipment nameplate can be customized and fabricated for a specific thickness, finish, and attachment method. They have a wide range of finishing options, such as matte, satin, brushed, and gloss. Also, different colors can be used for plate graphics, but shades other than black are not as UV resistant and may fade or degrade over time. A tag can be attached to a surface using a durable adhesive or physical means, such as screws or nails.

Enterprises have different types of equipment and therefore require various labels. Metal tags are popular in harsh environments because of their strength and durability. Focusing on their use case and capabilities enables companies to take advantage of their features.