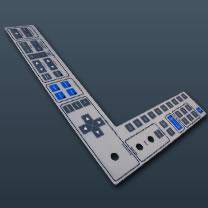

Custom graphic overlays can be found just about everywhere. They’re used to augment machines, control panels, and interfaces as a convenient way to share information. These overlays are often branded with company logos and seamlessly designed to fit with the control panel and the equipment. A graphic overlay can also include text, images, and other elements to create a truly unique design.

Graphic overlays promote safety and help reduce any confusion that might occur when interacting with equipment hardware or interfaces. They also create an added layer of protection for the underlying electronics to help reduce damage and contamination from the surrounding environment. In this post, we’ll explore several important factors to look for when choosing graphic overlays for your applications.

Graphic Overlay Layers

Familiarizing yourself with the construction of graphic overlays will help inform your purchasing decisions. Each overlay consists of a base material, printed surface, and adhesive. The base material should be selected first based on the application requirements. Printing can be done on the bottom (subsurface) layer of a plastic overlay so that the image itself is protected from any direct contact or exposure to environmental elements like UV light.

Some designs can also support translucent windows or textures to create unique overlay features. An adhesive is often one of the last design choices and is selected based on the materials of construction for both the overlay and the surface where it will be attached.

Substrate Materials

There are several materials available for graphic overlays, with each having performance qualities that are best suited for particular use cases. We’ll look at the most popular materials and which applications they’re best suited for. Many of the substrate materials shown are available in a variety of thicknesses that can be chosen based on the level of panel flexibility and durability required.

- Vinyl. Many customers choose vinyl as an economical option for creating graphic overlays that are durable and flexible. This material is also an excellent choice for signs and labels due to its resistance to moisture and abrasion.

- Polyester. Polyester is another graphic overlay material that is especially resistant to chemicals and high temperatures. Many keyboard overlays are fabricated with vinyl as they can withstand frequent contact without major degradation of image quality.

- Polycarbonate. Polycarbonate is a durable and firm material that can be used to create overlays for outdoor equipment and other demanding applications. Printing onto this material creates high-resolution, sharp images that are easily visible.

- Aluminum. Anodized aluminum is one of the most common metals used to fabricate graphic overlays. This is a great choice for military and marine applications and is best used when ordered in high-volume production quantities.

- Metalphoto® AnodizedAluminum. Metalphoto has become one of the most popular materials for durable graphic overlay applications. Metalphoto also supports high-resolution graphics and has an expected lifespan of 20 or more years, even in harsh outdoor environments.

Product Features

The materials of construction for your underlying product should also be considered when selecting a graphic overlay. Not all materials can be attached together in a cohesive way, so it’s often recommended to choose an overlay substrate that complements the product.

Product shelf life should also be reviewed, and the best graphic overlay choices are those that will last at least the expected lifespan of your product. Your equipment may also contain unique surface contours that require custom overlay designs. Finally, you should always choose colors and branding that lend to intuitive operation and can be appreciated by your target customer base.

Graphic Overlay Fabrication

It can be helpful to consult with your production partner to review the fabrication process for your graphic overlays. Choosing a final finish, such as gloss or matte, can add an aesthetic appeal to your final design. Many of the finishes will also add a protective layer to the overlay that can further reduce the likelihood of environmental contamination. Also, you should discuss the customization offered for your graphic overlay so that you can choose a layout that fits perfectly with your final product design. For example, die-cutting can often be used to create unique graphic overlay shapes that will fit in even the most unique shapes and sizes.

Graphic overlays are a great option for product designers and companies that desire a custom solution for marking their products, user interfaces, and control panels. Always consider the environmental conditions when selecting a substrate material and choose a design that works best for your intended end-users. You can also customize many aspects of your graphic overlays based upon your budget and order quantities.