Home Anodized Aluminum Labels & Tags

Anodized Aluminum Labels, Tags and Custom Aluminum Stickers

The Aluminum With Superior Abrasion Resistance

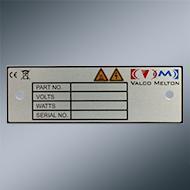

MPC’s Anodized Aluminum Labels, Custom Aluminum Tags and Stickers are an ideal choice for manufacturers that require exceptional abrasion resistance tags and labels. Graphics are sealed beneath an anodic layer that is impervious to weather, with excellent resistance to abrasion, corrosion, chemicals and solvents.

MPC’s anodized aluminum labels and tags are available in foil or rigid thicknesses:

-

-

-

- Foil Anodized Aluminum pre-printed labels are available in .003″, .005″ and .008″ thicknesses.

- Rigid Anodized Aluminum pre-printed labels are available in .012″ to .125″ thicknesses.

-

-

Why Choose MPC's Anodized Aluminum Labels, Tags or Aluminum Stickers?

- Provides superior resistance to abrasion, chemicals, solvents, and extreme temperatures. Images are sealed beneath the anodic layer for increased durability and weather resistance.

- A cost-effective alternative to Metalphoto in select applications.

- Mechanical attachment using high-performance adhesive and/or holes.

- Black graphics offer the greatest durability with an expected exterior life up to 10 years on all tags and labels. Color options are less UV-resistant and are not recommended for long-term outdoor use.

- Manufactured using anodized aluminum face stock. After fabrication, edges and holes of the finished parts are not anodized; a secondary process may be elected for thicknesses of .063" or greater to anodize, alodine or paint these edges for increased durability and protection.

Product Specification

| Material: | Anodized aluminum face stock (optional thicknesses .003", .005", .008", .012", .020", .032", .063", .090", .125"). |

| Finishes: | Matte (non-reflective with flat finish), Satin (lustrous semi-reflective material), #4 (brushed to resemble a stainless steel finish), Gloss (highly reflective, mirror-like). Note: #4 starts at .032" thickness; Gloss is available in .020" only. |

| Attachment: | Permanent pressure-sensitive adhesive and/or holes for mechanical attachment. |

| Copy/Graphics: | Many fonts and design elements are available, as well as your company logo. |

| Colors: | Color options available. Note: Colors have limited UV resistance. Not recommended for long-term outdoor use. |

| Standard Sizes: | Standard and custom sizes. |

| Shipment: | 15 working days from receipt of order and approval of artwork. Expedited shipment is available for an additional charge. Foil thicknesses require 15-20 working days. |

Benefits of Anodized Aluminum Labels

Anodized aluminum is a popular material used to make various components such as tags, stickers, and signs due to its light weight, affordable price, and durability. Metal stickers and tags made of anodized aluminum are an excellent choice for a permanent labeling solution. These are a few of the most recognized benefits of this material.

- Durable and Lightweight. Anodized aluminum is resistant to scratches from sources of abrasion and other contact hazards. It can be used in industrial settings and other demanding environments without concern for surface damage or reduced readability. The high-contrast graphics are sealed beneath an anodic layer of aluminum, which helps to protect the surface and preserve the integrity of the graphics. Anodized aluminum tags and stickers perform especially well in outdoor environments and can last for up to 10 years even with exposure to harsh weather conditions.

- Color Selection. Some materials can be printed with a limited number of color options, but anodized aluminum can be processed with a wide variety of color graphics. The main drawback of color graphics is reduced UV resistance. Care should be taken for any outdoor applications with the potential for long periods of sun exposure. Color printing has the same high contrast and excellent readability that are expected with anodized aluminum labels. For applications requiring labels with the durability to withstand direct sunlight exposure, Metalphoto® anodized aluminum is a better choice, with an expected lifespan of up to 20 years in outdoor environments without fading.

- Flexible Attachment. Anodized aluminum is one of the few materials that can be used to make labels that are extremely thin yet still have a high surface strength. Anodized aluminum foil labels can also be placed on uneven surfaces and curved equipment such as pipes and cables. Since these aluminum stickers also use a high-performance, permanent pressure-sensitive adhesive, they are difficult to remove, adding another layer of protection that can be found with similar security labels and tags.

Common Use Cases for Custom Aluminum Tags

Custom anodized aluminum tags and labels are a standard component of many asset management systems. With such a balance of cost and durability, customers can purchase a high volume of custom aluminum tags, even for the largest fleets and inventories, at an affordable cost. Among the many applications for custom aluminum tags, these are a couple of the most common use cases.

- Product Identification. Anodized aluminum is an excellent material choice for product identification and asset tagging purposes. With both rigid and foil options available, anodized aluminum tags and labels can be attached to nearly any surface and printed with barcodes for more efficient inventory management. For situations that require a customized, durable, and affordable solution, anodized aluminum tags and labels are a good choice for many applications.

- Military Data Plates. While Metalphoto® anodized aluminum is often chosen for the most demanding and challenging environments, standard anodized aluminum labels remain a popular choice for many other applications in these industries. Military, aerospace, and maritime businesses all benefit from custom anodized aluminum stickers, labels, and tags. With strong resistance to water, chemicals, and UV rays, anodized aluminum is a high-quality material suitable for military data plates. The military industry is highly regulated with many requirements and specifications, so material selection is always an important consideration. In some military standards and aerospace applications, Metalphoto® is specified as the material to use, so it’s crucial to consult all applicable standards and regulations before choosing materials for tags and labels for use in these industries.

No minimum quantity. Get a quote for any size job.

Get a quote for any size job – we have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

No minimum quantity. Get a quote for any size job.

Labels & Tags