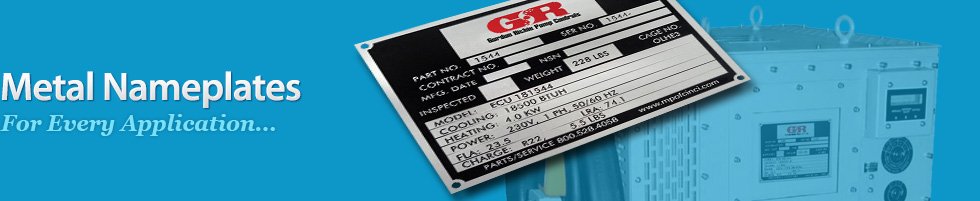

Home Metal Nameplates

Custom Metal Nameplates

Tough in Outdoor and Industrial Environments

Why Choose MPC's Metal Nameplates?

- Provide years of durability, remaining readable for the life of your part or equipment.

- Require little maintenance, at a competitive price.

- Versatile selection of substrates offer resistance to weather, UV, extreme temperatures, chemicals, abrasion, corrosion and dents and scratches.

- Advanced fabrication capabilities reduce lead times and costly tooling charges.

- Knowledgeable staff work to understand your application and deliver the metal nameplate that meets your exact specifications.

Metal Nameplate and ID Plate Choices

Our most durable and popular material, the preferred choice for environments requiring extreme durability.

- High-resolution graphics sealed beneath an impenetrable sapphire-hard anodic layer.

- Superior resistance to chemicals, abrasion and solvents.

- Built to withstand exterior exposure in the harsh environments such as extreme cold, heat and UV. Expected exterior life of 20+ years. Color options have limited UV resistance.

- Most cost-effective for small to medium volumes.

An ideal choice for use in the aircraft/aeronautical, automotive, marine and military industries, with anodized surface with a virtually impervious protective finish to protect data.

- Well-suited to applications requiring resistance to abrasion and corrosion, as well as moderate outdoor durability.

- Excellent resistance to chemicals and solvents.

- More economical in higher-volume applications.

- Graphics are screen printed and sealed beneath the anodic layer. Black graphics offer the greatest durability, with expected exterior life up to 10 years. Color options have limited UV resistance.

A lightweight yet strong material that is easily formed, aluminum is a popular choice for data and nameplates for its machinability and versatility.

- Used in applications such as aircraft, marine, military and transportation.

- Moderate outdoor durability and heat resistance. A protective coating increases abrasion resistance. Expected exterior life is up to 10 years.

- Less expensive than many other metals.

- Graphics may be printed on the surface or chemically etched.

A dense metal with exceptional resistance to chemicals and corrosion, ideal for marine, heavy industrial and food processing applications.

- Frequently used in highly caustic and acidic environments that would otherwise attack aluminum and destroy most data plates.

- Offers low maintenance and dent and scratch resistance.

- A relatively inexpensive material when lifetime cost is examined. Expected exterior life of up to 20 years.

- Graphics may be printed on the surface or chemically etched.

Known for its rich color and beauty in decorative applications. A popular choice for high-end retail and commercial displays, as well as applications requiring outdoor durability.

- Excellent resistance to saltwater, chemicals and corrosion make it well-suited for marine, military, and general industrial applications. Expected exterior life is up to 20 years.

- Generally less expensive than stainless steel.

- Graphics may be printed on the surface or chemically etched.

Why do you need metal ID plates and metal nameplates?

Metal ID plates are often chosen for their excellent durability and ability to withstand harsh conditions. Companies in the aircraft, automotive, marine, and military industries utilize metal ID plates and nameplates for a variety of applications, and they are an excellent choice for situations that require a permanent application that can last for many years. Metal nameplates can be custom fabricated to fit instrument panels or unique form factors, which makes them suitable for labeling nearly all types of equipment.

Many of the materials used to create metal ID plates are very affordable, especially in mass quantities, which makes them accessible to numerous industries and a wide range of budgets. When preparing to request a new metal ID plate or nameplate, it’s always best to consider your specific application, so that the fabricator can best match the material type, adhesion level, thickness, and size of the plate to your needs. The company can also select the optimal material based on your expected level of abrasion, corrosion, and temperature exposure.

One of the main uses of metal nameplates is the labeling of equipment. Metal ID plates and name plates can be custom printed with serial numbers, barcodes, and unique designs, such as designs for instrument panels. This flexibility allows the equipment owners and operators to create nameplates that fit seamlessly with their equipment. They can also be branded with company logos to display asset ownership and other information.

Common uses for metal nameplates

When designing a metal nameplate, it’s always necessary to select a material type based on the customer’s application and project requirements. Brass and aluminum are two of the most affordable metal choices and are often used for nameplates, panels, and signs. Both materials are very resistant to corrosion, and brass is resistant to saltwater as well. Stainless steel is a dense metal that is also known for its excellent chemical resistance. Anodized aluminum offers some improved strength versus standard aluminum, and Metalphoto® provides the highest level of durability.

Metal tags are commonly used in the boating industry in order to meet USCG documentation standards and requirements. In order to remain compliant with regulatory requirements, many boat owners need to supplement existing nameplates and ID plates on their vessel with additional notifications. It can also be necessary to replace old or worn identification panels over time. Some of the types of metal nameplates that are regularly installed include capacity labels, warning labels, instrument panels, and safety labels.

Several metals can be used in aerospace applications, and one of the most popular is Metalphoto®. According to the National Association of Graphic and Product Identification Manufacturers (GPI), Metalphoto is considered the most durable among aluminum substrates. For this reason, it is used widely in the military, aerospace, and aviation industries. Given the potential altitudes for assets used in these industries, the metal nameplates must be able to withstand extreme temperatures and long periods of UV exposure. Since the metal labels can also be certified according to industrial and military standards, they make a very dependable choice for these high-demand industries.

No minimum quantity. Get a quote for any size job.

No minimum quantity. Get a quote for any size job.

Get a quote for any size job – we have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

Nameplate Products