Home Aluminum Nameplates

Aluminum Nameplates

Lightweight Yet Durable

MPC’s aluminum nameplates are a popular choice because of their light weight and ability to resist corrosion. Aluminum is a strong metal known for its low density and is softer than anodized aluminum, allowing it to be easily machined and formed. Its familiar silvery-white luster offers great contrast and readability in nearly any color. Aluminum nameplates tend to be more economical than other metal nameplates.

Graphics and copy may be screen printed or chemically etched with or without a color-fill. An optional protective coating is often applied for increased abrasion and scratch resistance. Expected exterior life is up to 10 years. Color options have limited UV resistance and are not recommended for long-term outdoor applications.

Why Choose MPC's Aluminum Nameplates?

- Durable, lightweight and malleable.

- Skillfully fabricated in our machine and print shops to your design specifications.

- Expected outdoor life of up to 10 years, with high resistance to corrosion, oxidation and extreme temperatures.

- An optional protective coating can increase abrasion and scratch resistance.

- High-performance adhesives and/or holes for mechanical attachment.

- Graphics and copy may be screen-printed or chemically etched with or without a color-fill.

Product Specification

| Material: | Aluminum .020" face stock standard (optional thicknesses .003", .005", .008", .012", .020", .032", .063", .090", .125"). |

| Finishes: | Matte (non-reflective w/flat finish), Satin (lustrous semi-reflective material), #4 (brushed to resemble a stainless steel finish), Gloss (highly reflective, mirror-like). Note: Finish options may vary by material thickness. |

| Attachment: | Permanent pressure-sensitive adhesive and/or holes for mechanical attachment. |

| Copy/Graphics: | Many fonts and design elements are available, as well as your company logo. |

| Colors: | Color options available. Note: Colors have limited UV resistance. Not recommended for long-term outdoor use. |

| Standard Sizes: | Standard and custom sizes. |

| Shipment: | 15 working days from receipt of order and approval or artwork. Expedited shipment is available for an additional charge. Foil thicknesses require 15-20 working days. |

Benefits of Aluminum Nameplates

Aluminum is known for its versatility and offers a good mix of strength and affordability. It is an ideal metal substrate to use for nameplates since it can be custom fabricated for applications in nearly any industry. Aluminum is a popular metal that’s quite affordable, so it’s especially useful for companies that require high volumes of nameplates. Here are a couple of the most important benefits that aluminum nameplates offer to the market:

- Lightweight and durable. Because standard aluminum is low-density, this makes the metal flexible, and it can be easily molded and formed into custom nameplate shapes. Its combination of light weight and durability makes aluminum an excellent choice for nameplates in any standard equipment environment. Aluminum also offers corrosion resistance and can be placed in many different environments. Nameplates that are exposed to especially harsh conditions would benefit from the added protection of anodized aluminum, such as Metalphoto®, which can withstand exposure to direct sunlight and has an outdoor durability rating of more than 20 years without fading.

- Clear and clean presentation. Aluminum has a very nice luster, which provides an excellent contrast between the metal and graphics when it’s printed on. This attractive finish is a main reason why it is used so often for equipment nameplates. Aluminum nameplates complement the equipment surface and maintain a professional look. Standard aluminum is also a very economical choice for nameplates with a variety of sizes, finishes, thicknesses, and colors available.

Common Uses for Aluminum Name Plates

Aluminum name plates are used throughout the world for applications in industries such as food and beverage, heavy industry, and aerospace. They’re also used in high-demand marine and military work environments. The numerous finishes available for aluminum, including matte and gloss, give manufacturers and equipment owners the ability to customize the look of their name plates. While aluminum may be used in nearly every industry, here are two of the most popular applications for aluminum name plates:

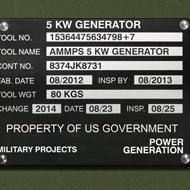

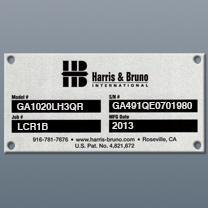

- Equipment identification. Name plates are often attached to equipment for identification purposes after purchase. A company often will create a standard template for their labels that can then be affixed to any new equipment to identify property ownership. Name plates printed on aluminum are available with a large number of options for colors, finishes, and fonts. This makes them an attractive choice for nearly any warehouse, factory, or office environment that requires equipment identification plates. Some equipment is also moved frequently within a building environment, and the abrasion resistance of aluminum helps protect the plate surface from any contact.

- Product labeling. When preparing a product for shipping, a company will often affix a permanent name plate to the product that identifies the manufacturer. This is especially common for nearly any type of industrial or specialized equipment. Aluminum name plates are durable and can be readily shaped and molded to fit any unique equipment surface contours. They usually are attached to the equipment with high-performance adhesive or mechanically with bolts. Companies that use aluminum name plates can have confidence that their product labels can survive the wear-and-tear of shipment and use.

No minimum quantity. Get a quote for any size job.

Get a quote for any size job – we have no minimum piece requirement. Our minimum production run is $400 per part number, excluding set-up fees/tooling. Contact us regarding your project.

No minimum quantity. Get a quote for any size job.

Nameplate Products